Gravity Flow Racking Systems

Gravity Flow Racking Systems Read More »

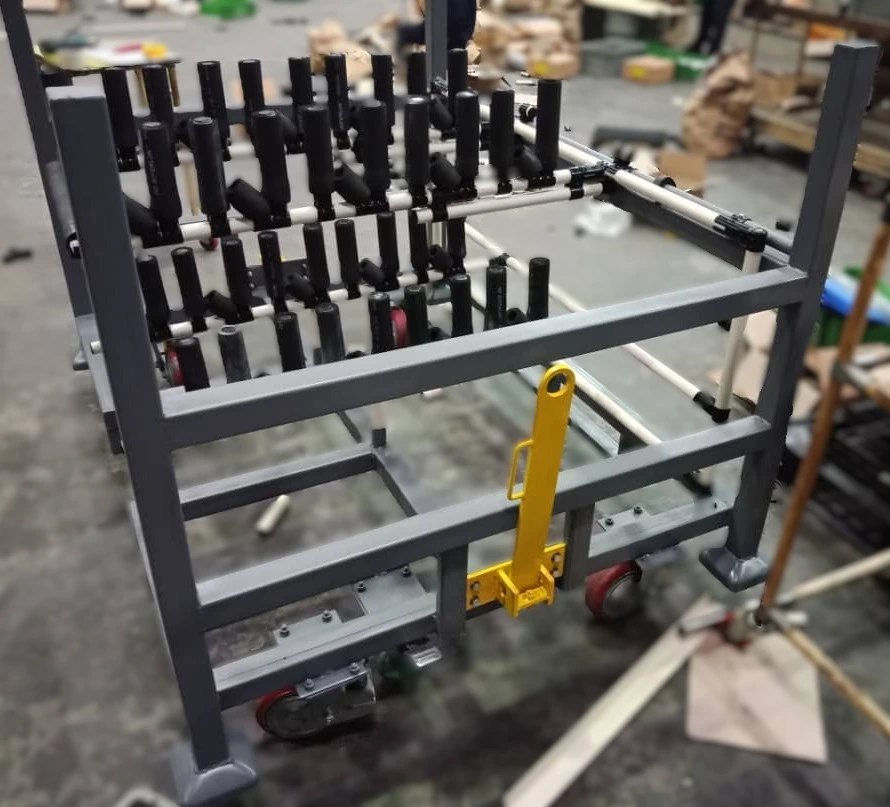

Pipe Racking and Joint Systems consist of modular frameworks from pipes and joints, allowing businesses to create custom storage and material handling solutions. Industries focused on lean manufacturing often rely on these systems because they enable quick adaptation and optimisation of workflows.

Aluminium Pipe Racking and Joint Systems

Steel Pipe Racking and Joint Systems

Custom Metal Fabrication

Modularity: These systems offer high modularity, allowing you to reconfigure them to meet changing operational needs easily. You can add or modify components without causing significant downtime.

Customisation: They enable you to design solutions tailored to specific storage or material handling requirements, making them ideal for diverse industries such as automotive, electronics, and manufacturing.

Durability: Built from robust materials like steel or aluminium, these systems withstand heavy loads and continuous use, ensuring long-lasting performance.

Lean Manufacturing: By improving workflow efficiency, reducing waste, and optimising space utilisation, these systems directly support lean manufacturing principles, helping you streamline operations.

Ease of Assembly: Designed for quick assembly and modification, they allow your business to adapt to new challenges without the need for specialised tools or expertise.

Warehouse Storage: Use these systems to create adaptable shelving units that you can easily reconfigure as storage needs change.

Assembly Lines: Build customised workstations or flow racks to enhance production efficiency by organising tools and materials effectively.

Automotive Industry: In the automotive sector, these systems help you handle and store various components and parts, with the flexibility to reconfigure the setup for new models or parts quickly.

Electronics Manufacturing: In electronics manufacturing, these systems streamline the organisation and management of small parts and components.

Overall, pipe-racking systems are critical for optimising material handling processes. Businesses that adhere to lean manufacturing principles can effectively and adaptably implement these systems to improve efficiency.

Abs Costed Steel

Plastic

Stainless Steel

Aluminium

Choose from the above material list suitable for your application, budget or application requirements.

Below are a few examples of our pipe-racking system application for your reference:

Aluminium Pipe and Joint Systems Ladder Step Design

Overhead Platform by Aluminium Pipe Racking Systems

Combine Welding Base Frame & Pipe Racking System.

Combine Welding Base Frame & Pipe Racking System.