Introduction to FIFO Management

FIFO (First-In, First-Out) is a proven storage management method that ensures older products are used or shipped first. Consequently, it helps businesses maintain product freshness, reduce waste, and improve overall inventory accuracy. In industries where product shelf life, batch control, and traceability are critical, implementing FIFO is essential for smooth, efficient warehouse operations.

FIFO VS LIFO – Understanding the Difference

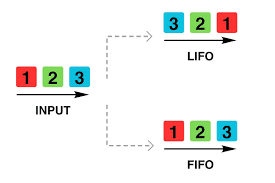

By following FIFO principles, warehouses ensure older inventory moves out first, helping protect product quality and shelf life.

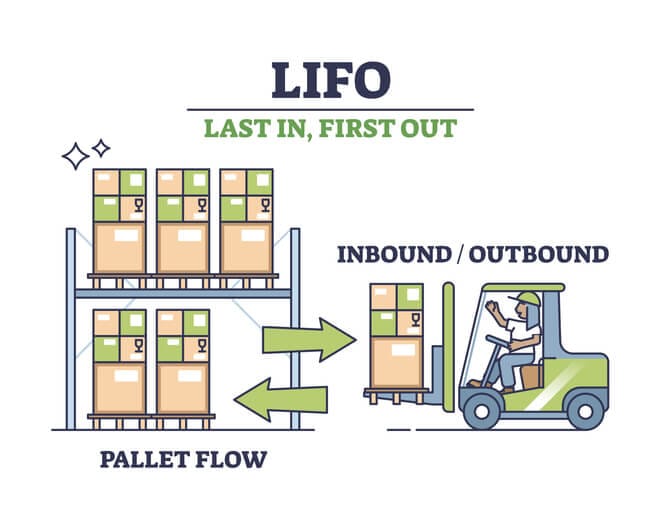

LIFO (Last In, First Out) picks the newest stock first, sometimes used in bulk storage or for specific accounting strategies.

Choosing the right method depends on your product type, warehouse layout, and operational goals.

| Inventory Method | Picking Order | Best For | Example |

| FIFO | Oldest stock first | Perishable products | Food,beverages,medicines |

| LIFO | Newest stock first | Bulk/non-perishable | Heavy industrial materials,packaging |

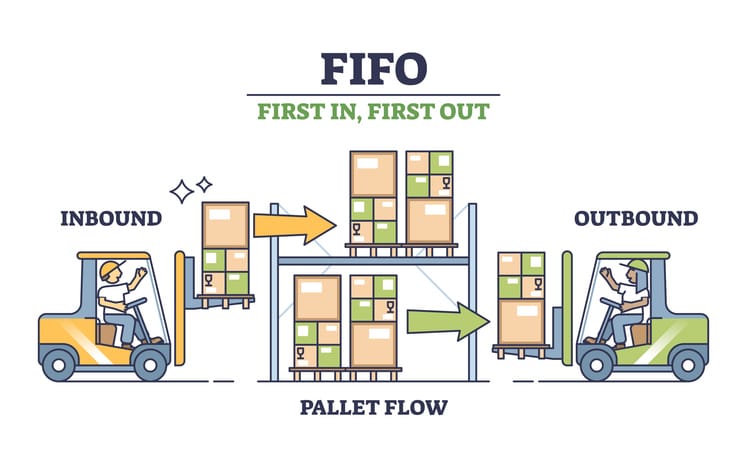

Below is a visual comparison of FIFO and LIFO inventory flow in warehouse operations.

How FIFO Inventory Management Works?

- Goods are received and stored at the loading side

- Products flow forward through storage lanes

- Pickers retrieve items from the opposite side

- Older stock is always dispatched first

To ensure proper stock rotation, FIFO works by organizing storage locations so that products move in one clear direction.

Why FIFO Is Important in Warehouses?

Implementing FIFO inventory management offers several operational benefits:

- Prevents product expiration and obsolescence

- Improves inventory accuracy and traceability

- Reduces waste and financial losses

- Enhances picking efficiency and workflow

- Supports regulatory and quality compliance

FIFO is a foundation of efficient and well-organized warehouse operations.

Storage Systems That Support FIFO / LIFO

Certain storage systems are specifically designed to support FIFO / LIFO inventory management, including:

- Gravity flow racking systems

- Carton flow racks

- Pallet flow racks

These systems use inclined roller tracks that allow products to move forward automatically, ensuring consistent stock rotation with minimal manual handling

Need Help Implementing FIFO/ LIFO in Your Warehouse?

We provide customized storage solutions designed to support FIFO / LIFO management based on your warehouse layout, product type, and operational requirements.

📞 Contact us today to discuss FIFO-ready racking systems and warehouse optimization solutions tailored to your business needs.

We Work With the Trusted Partners Globally.

At TMEH Group of Companies, we collaborate with esteemed partners from across the globe, each representing a reputable brand. Together, we provide high-quality solutions that effectively meet the needs of our clients worldwide.