Kanban Inventory System Explained for Warehouse Operations

Introduction to the Kanban Inventory System

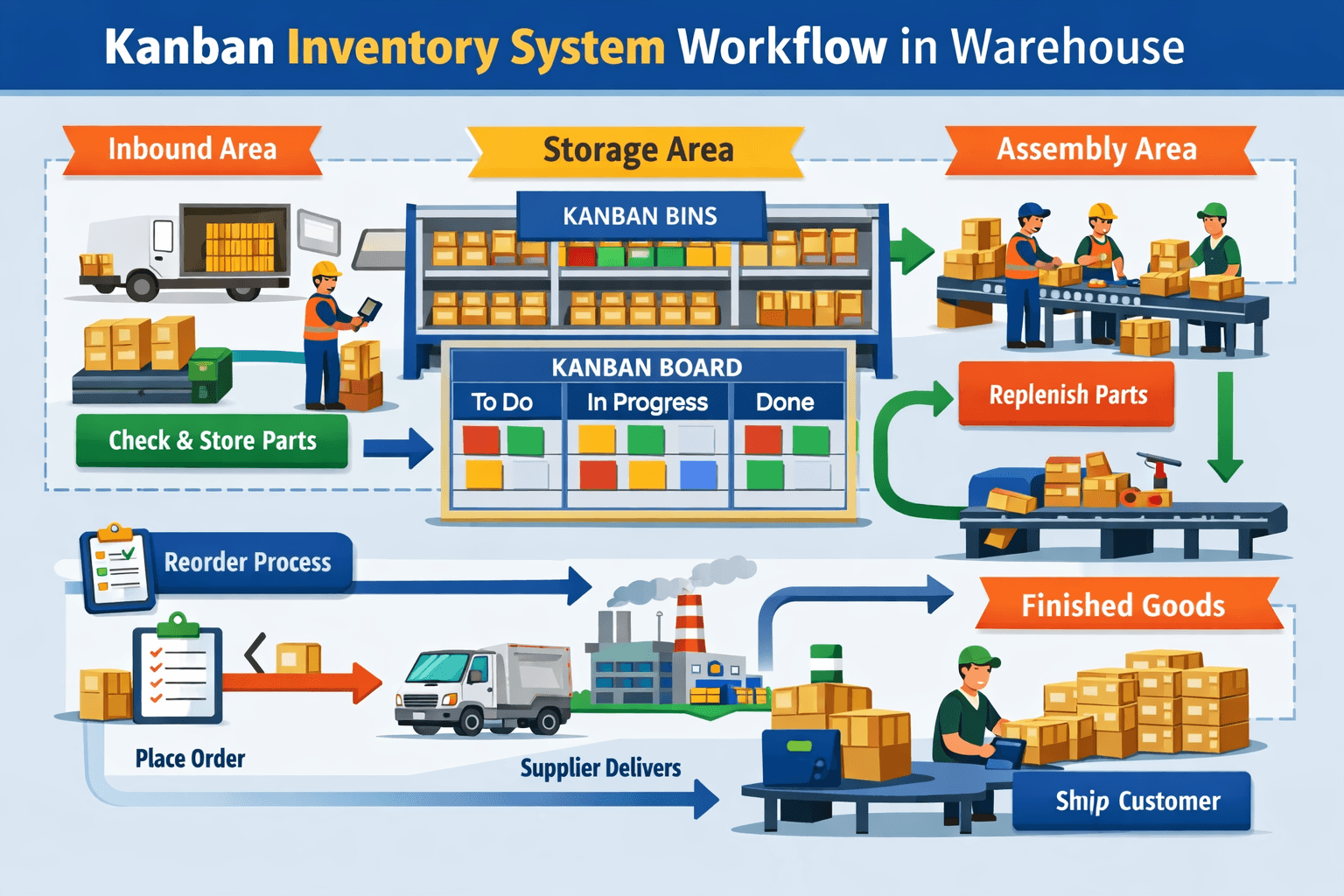

The Kanban inventory system is a visual inventory control method designed to regulate stock levels and improve workflow efficiency in warehouse operations. Originally developed as part of lean manufacturing, Kanban helps warehouses respond to real demand rather than forecasts.

By using visual signals, Kanban ensures inventory is replenished only when required, reducing excess stock and operational waste.

What is a Kanban Inventory System?

A Kanban inventory system is a pull-based method where replenishment is triggered by demand signals such as cards, bins, or digital alerts. Instead of pushing inventory into storage, Kanban allows stock to flow based on actual consumption.

Key characteristics include:

- Visual control of inventory

- Limited stock quantities

- Continuous replenishment cycles

- Reduced overproduction

How the Kanban System Works in a Warehouse

- Stock reaches a predefined minimm level.

- Visually can see the stock.

- Replenishment i initiated from storage or supplier.

- Inventory levels return to optimal range.

Benefits of Kanban Inventory Management

Implementing Kanban in warehouse operations provides several advantages:

Kanban vs FIFO – How They Work Together

Kanban and FIFO serve different but complementary purposes:

- FIFO (First in, First Out) controls the physical movement of inventory

- Kanban controls when replenishment should occur

- Together, they create a balanced and efficient inventory flow

Storage Systems That Support Kanban

Kanban inventory systems work best with organized and visible storage solutions, including:

- Gravity flow racking systems

- Carton flow racking systems

- Pallet flow racks

- Polybox (plastic container) and bin systems

These systems allow warehouse staff to quickly identify stock levels and respond to Kanban signals efficiently.

Industries That Use Kanban Inventory Systems

Kanban is widely adopted across various industries, including:

Need Help Implementing Kanban in Your Warehouse?

We provide customized warehouse storage and inventory solutions designed to support Kanban inventory systems.

Our team can help you plan layouts, select the right storage systems, and optimize inventory flow based on your operational needs.

📞 Contact us today to discuss Kanban-ready warehouse solutions tailored to your business.